Ratliff Metal Spinning is a full-service and premier provider of custom metal spinning services. We have been family owned for 50 years and have steadily grown our business by forging strong relationships with our customers while adhering to honest, ethical business practices. Our extensive experience in the metal spinning industry has allowed us to create a wide variety of parts at a fair price to satisfy customers with on-time delivery in the lighting, food services, aerospace, ventilation, and other industries. Contact us today to discuss your specific needs and learn more about our capabilities.

We are the source for all your metal spinning needs

Request a QuoteQuality isn’t expensive

it’s priceless

40 Harrisburg Dr.

Englewood, OH 45322-2834

(937) 836-3900

We have eight full CNC metal spinning work cells that allow for secondary operations to be performed simultaneously by a single operator. This not only increases productivity, but also enables high volume runs that yield consistent manufacture in a cost-effective manner to meet your delivery needs. For low volume runs and design prototyping we have skilled craftsman who can meet these demands on our manual metal spinning lathes.

We offer highly competitive, in-house produced spin tooling, pierce dies, and drill fixtures in our full service tool room. We can also provide milling and drilling operations along with secondary machining services to complete your parts.

We offer in-house fabrication services including MIG/TIG welding, turret and punch press operations, bead rolling, bending, roll forming, and PEM studding. We can efficiently offer these operations to accommodate our customers diverse needs.

We can provide external services to ensure your parts are complete from start to finish. Some example outside services that we can provide include heat treating, anodizing, painting, polishing, and laser cutting, among others.

We have a special talent in solving production problems to give you a greater cost-savings. Our engineering department, in conjunction with our 100+ years of combined metal spinning expertise, allows us to design tools that minimize cost in the most efficient way possible.

We have in-house, climate-controlled storage facilities for warehousing your finished products until they are needed. Our inventory management solutions are customer-driven and allow for stock inventory management for blanket order and just-in-time release options. This allows us to reduce lead times and material expediting fees, ensuring that your parts are shipped on time, all the time.

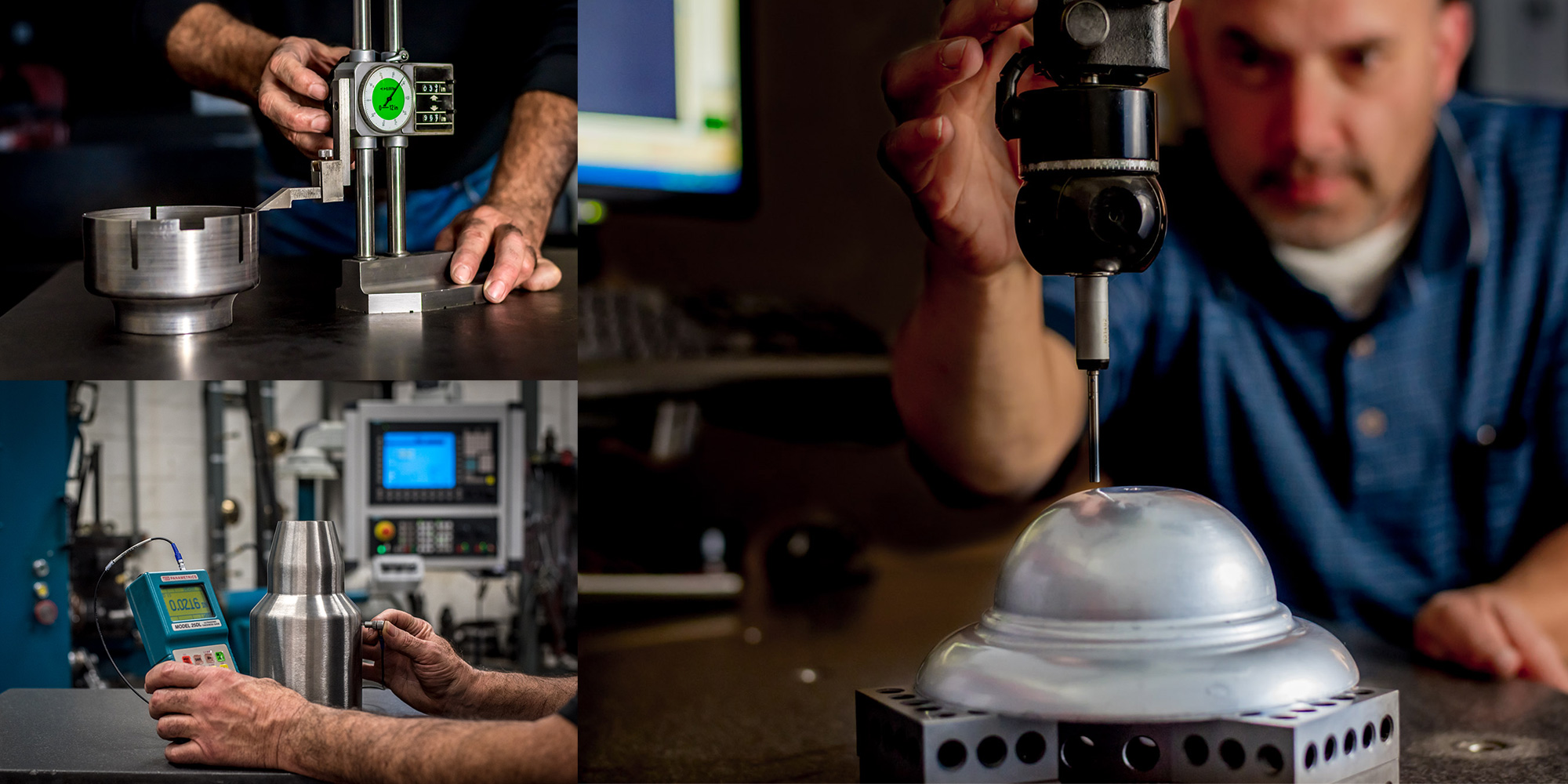

Quality assurance is an integral part of our manufacturing process and our modern inspection facility is ISO-9001 compliant. Our dedicated quality manager ensures the delivery of high quality parts that meet or exceed your quality expectations through part inspections both in our QA facilities as well as spot checks on the manufacturing floor.

We service a diverse set of customers representing a wide range of industries including commercial lighting, ventilation, food services, defense, aerospace, maritime, recreational equipment, infrared heating, automotive, and others. Our experience in manufacturing parts for such varied industries gives us a clear understanding of our customers' expectations and the ability to satisfy them.

- 8 CNC metal spinning work cells up to 63" diameter blank capacity

- 10 manual metal spinning lathes up to 82" diameter blank capacity

- We work with most all metals (alum 0.25", mild steel 0.375", stainless 0.125")

- Our work cell capabilities allow a single operator to multi-task ancillary operations, maximizing production to deliver cost savings and high quality parts

- Machining lathes up to 72" diameter capacity

- CNC machining up to 32" diameter capacity

- Vertical milling with 10" x 50" table size

- Surface grinding and wire burning

- Tooling design via CAD

- Circle shearing up to 78" dia. x 1/4" capacity

- Square shearing up to 12' x 3/8" capacity

- Punch pressing up to 100 ton and turret pressing up to 35 ton

- Press brake up to 8' x 75 ton capacity

- Roll forming up to 48" x 1/8" capacity

- MIG/TIG welding and PEM studding

We'd be glad to help you get started on your next project. It only takes a few minutes to contact us or request a quote.